Supply chain management is a long-term plan developed by a company to effectively manage its supply chain operations to achieve its business objectives It involves the planning and organization of goods and services from suppliers there to customers, including purchasing, manufacturing, transportation and delivery.

Strategic supply chain management typically considers factors such as company inventory, customer needs, market needs, product availability, and competitive environment. Moreover, the goal is to create flexible and efficient supply chains that deliver goods or high-quality services will be provided to meet the needs of customers at competitive costs and maximize profits. Getting to successful outcomes demands focused study, strategy, and careful steps. Additionally, this means teaming up with partners like providers, transporters, and other key players in the supply chain.

In this article, we’ll learn different techniques, utilized to refine supply chain management and the perks of introducing these techniques in managing the supply chain.

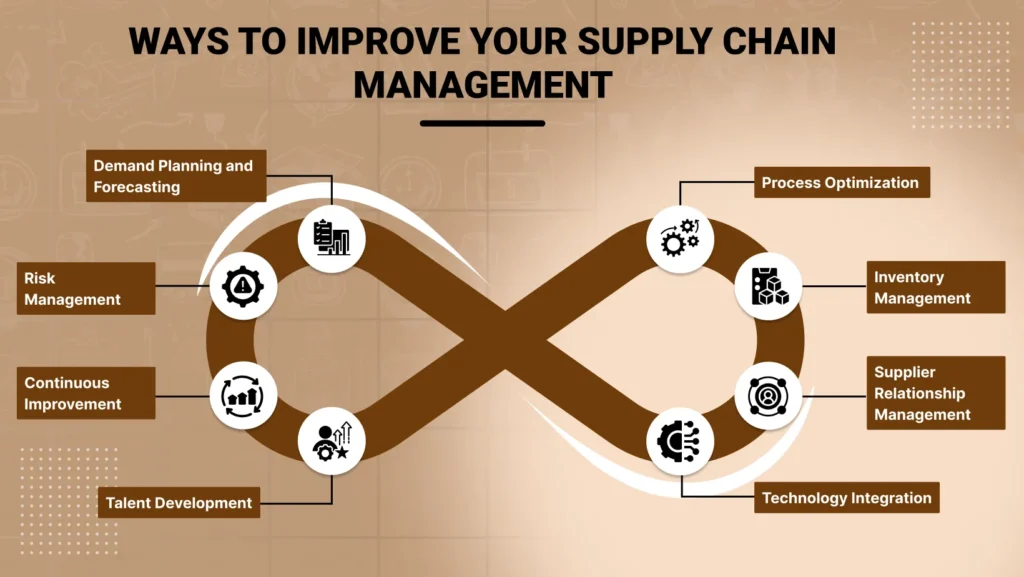

Ways to Improve Your Supply Chain Management

Process Optimization

Checking and fine-tuning supply chain processes is essential. This allows us to identify and eliminate bottlenecks, reduce waste, and improve operations. However, the first step is to map the entire supply chain, identifying bottlenecks and repeating or non-value-added activities. From there, lean principles can be applied to smooth operations. Tools such as value stream mapping, product reengineering, and continuous improvement strategies can be used.

Inventory Management

Determine how much inventory the company has. Keep only what you need; Nothing more than that. The cost of inventory and storage is very high. Inventory costs can represent as much as 60 per cent of the cost of keeping a product in storage for one year.

Include demand planning and forecasting to optimize company inventory. Another way to improve inventory is to use truck scales for better handling. The scale provides an accurate measurement that can help you determine the right number of items to put in your collection. However, inventory management strategies help businesses maintain appropriate stock levels and reduce storage costs. JIT (Just-in-Time), vendors-managed inventory, demand-led tactics, and many more. To find the right balance between stock level and consumer demand, leveraging technology such as barcode scanners, automatic inventory monitoring systems, accuracy and clarity of inventory visibility, and many more.

Supplier Relationship Management

Poor relationships with suppliers can lead to significant issues and additional costs that can reduce your bottom line. In a market where there are no suppliers, there are no items or products to sell. High-quality, affordable, and high-value products help your company grow. Good suppliers who can provide high-quality products for a reasonable price will keep your customers satisfied. Consequently, the ongoing support they provide will help your company make more money and increase profits. Your relationship with the supplier has an impact on the success of your supply chain. Cultivate and maintain supplier relationships regularly, even after deals are closed. Furthermore, focus on developing strategies to sustain healthy supplier relationships. Set goals for continuing value. Measure performance and maintain conflict resolution.

Technology Integration

Establishing strong team relationships with suppliers is essential for a reliable and efficient supply chain. This involves planning, staying in touch regularly, monitoring their progress, and continually striving to do better. Furthermore, to ensure suppliers meet our expectations, we set targets and key performance indicators (KPIs) to help firms align with suppliers’ goals and quality standards.

Utilize technology to enhance supply chain performance. Review current processes that are delivering subpar results. Identify areas where implementation of technology could improve processes. The right technology, such as industrial-scale technology, can make a supply chain more efficient, transparent and accessible.

Demand Planning and Forecasting

The planning step is to match your supply with demand for your products/goods. Production planning and demand planning help you understand what you need to set goals to meet customer needs and what you need to invest to meet those goals. To improve your planning, you need to look at your warehouse space as well as your inventory spending.

Businesses need to accurately forecast inventory demand and supply performance to remain profitable. Demand and supply forecasts are important to keep inventories low and prices stable. For those who manage supply chains, it’s important to understand deeply how different factors might affect the demand for what they offer, such as the economic climate, competitor activity, and customer preferences. Understanding demand accurately means knowing how unique parts of the supply chain work together. When changes in customer demand are predicted and production is adjusted to match, money is saved, and earnings are not hurt.

Risk Management

Identifying and managing potential risks within the supply chain is essential for keeping businesses to be stable and resilient. However, it also requires risk checks, backup plans, and risk management strategies such as having different suppliers, duplicates, or protections like insurance or contracts. Moreover, being alert with early warning systems lets businesses spot and handle potential slowdowns better.

However, the method of spotting, evaluating, and addressing all risks throughout the entire supply chain is called Supply Chain Risk Management (SCR). As a supply chain contains all the elements and steps needed to produce and deliver a product, any disruption can create significant ripples in a company’s profits. An SCR plan establishes processes after evaluating both daily and edge case risks throughout the supply chain to minimize company vulnerabilities and ensure business continuity.

Continuous Improvement

Supply chain management isn’t a one-size-fits-all solution. Businesses needed to continually monitor the performance of their supply chain––by monitoring key indicators. They also needed to keep up with market changes. A well- functioning supply chain can adapt to unexpected events, such as natural disasters or supply chain disruptions. This requires frequent monitoring, input from third parties, and a constantly evolving culture.

Talent Development

Supply chain talent management is the strategic and systematic process of sourcing, recruiting, developing, and retaining talent to meet an organization’s immediate and long-term human capital needs. Talent flows are managed using workforce analytics to predict talent demand, talent acquisition and deployment optimization, talent leakage, and seamless integration of HR processes with broader business goals. Consequently, the goal is to create a robust talent pool that can be mobilized to drive organizational performance as needed.

Supply chain talent management is an important strategy for organizations looking to succeed in today’s competitive environment. Moreover, understand evolving supply chains, employer brand building, targeted business strategies, focus on business development, competitive compensation and benefits and work culture which they do together.

Sustainability Initiatives

“Supply Chain Sustainability” or “SCS” covers the eco-friendly and socially responsible operations of a company’s supply chain. However, those in supply chain professions help organizations accomplish sustainability. It’s done by minimizing environmental damage and advancing social fairness. Supply chain bosses strive to build a greener supply chain.

These steps usually align with the company’s environmental and social conduct (ESG). The objectives drive this process. The perks of sustainability are reduced costs, an effective supply chain, and a better company image. Additionally, an EY report on the main elements of successful supply chains gave interesting insights. According to top supply chain execs, potential revenue growth, and pressure from partners, customers, and employees, were the main reasons.

Collaboration and Communication

Communication is essential for coordinating all supply chain efforts and delivering products on time. A McKinsey report found that companies that worked with suppliers regularly saw more growth, lower operational costs, and higher profitability than those that did not. When your internal product team and outside supply chain partners regularly work on design changes during the NPD process, it ensures interoperability, and the final design is manufacturable and reduces the risk of production and quality issues in the future.

Extending collaboration across all levels of your supply chain allows for a more efficient exchange of information—improving component forecasting, reducing lead times, streamlining procurement, and increasing productivity. As teams start sharing information regularly, manufacturers gain more insight into operational challenges and reduce supply chain risks.

Conclusion

In summary, supply chain apps are changing the way you manage your supply chain. They give you real-time insight into your operations and allow you to communicate directly with your customers and stakeholders. However, two important objectives for supply chain management companies are on-time delivery and real-time information. Solution researchers help many companies achieve these goals and deliver better services.

By developing cross-platform applications, our company provides users with access to a wide range of products and services that streamline operations, increase connectivity and improve user experience. However, we work with some of the world’s top development and services companies like AppVin to facilitate access to innovative solutions and build relationships built on trust and shared purpose.

FAQs

What are the 4 pillars of supply chain strategy?

The four pillars of supply chain strategy are Integration, Visibility, Flexibility, and Sustainability.

How to build a supply chain strategy?

To set up a supply chain:

1. Define Objectives: Clearly define objectives that align with business objectives.

2. Review the current situation: Analyze the existing supply chain, strengths and weaknesses.

3. Design Strategy: Develop a plan considering factors such as sourcing, manufacturing, distribution, and customer service.

4. Resource implementation: Implement the program with appropriate resource allocation and process improvements.

5. Review and adjust: Continuously review business metrics and make design changes to meet evolving needs and challenges.

What is a strategic SCM?

Strategic supply chain management, or SCM, is about long-term planning. This supply chain activity aligns with larger enterprise objectives. It’s all about making smart choices. However, network design, identifying suppliers, how to source, and distribution measures. The goal? Improving quality, reducing costs, and staying ahead of the competition.

How can we improve supply chain management?

Making supply chains better needs better links, oversight, adaptability, and lastingness. We can do this by using tech, data analysis, and team effort. Always getting better and lowering risks also help to make supply chains work smoother.

What are the strategies of supply chain management?

Common strategies include inventory management, enhancing supplier relationships, Process Optimization, Demand Planning and Forecasting, Technology Integration, and many more.