Supply chain analytics (SCA) is a set of frameworks and tools for integrating and analyzing data across multiple systems to gain insights into sourcing, processing and distribution. When you combine data from your SCM and ERP applications, it provides you get a comprehensive view of your logistics ecosystem.

In most organizations, supply chains are now more complex than ever before, and they generate huge amounts of data that need to be looked at. For instance, in Ventana Research’s “Supply chain planning with prescriptive analytics” (2018), 78% of the companies surveyed said they only use spreadsheets (and only for supply chain planning) to plan their operations.

In 2021, supply chain professionals will be ranked superior among the businesses, supply chain analytics (SCA) as a critical technology investment, recognizing its significance in today’s global. It is beneficial for constructing a properly functioning ecosystem that may be looked at after optimized for improved overall performance.

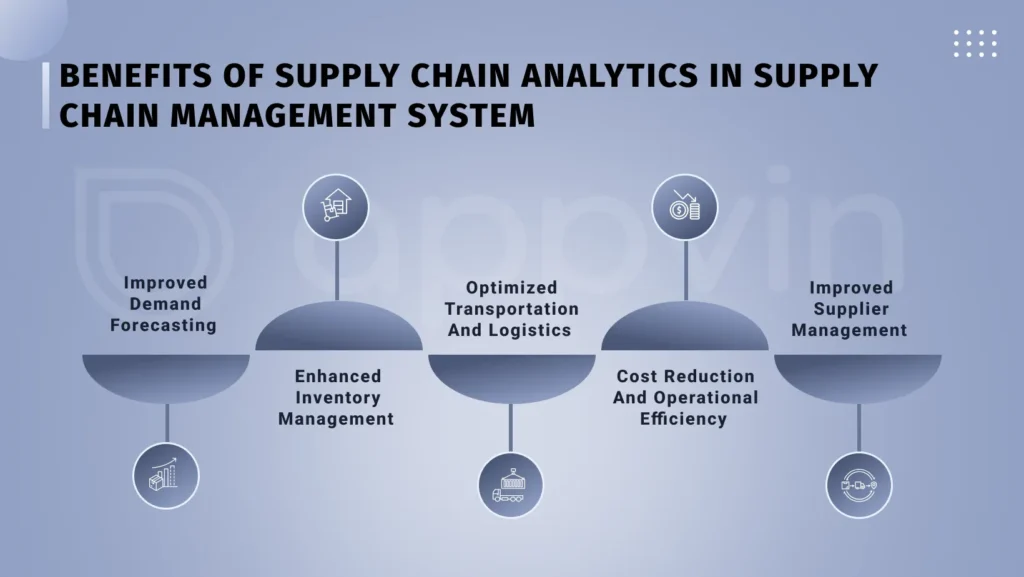

Benefits of supply chain analytics in supply chain management system

Improved Demand Forecasting:

Demand forecasting is centered around the customer. In industry, supply chain planners must rapidly grasp customer needs, preferences, and actions to make informed decisions on production, inventory, and distribution.

Companies can improve their supply chain management by accurately forecasting future needs to prevent deficiencies, reduce lead times, increase availability, and supply appropriate resources offering it, in the right quantities, at the right times and places

Demand forecasting involves planning and forecasting demand for goods and services to maximize value for businesses. Failure to accurately forecast demand can lead companies to waste excessive inventories or miss potential opportunities through unexpected customer needs, preferences and buying behaviors.

Enhanced Inventory Management:

Controlling inventory is a perpetual challenge unless supported by smart supply chain analytics. Having insufficient or excessive inventory has an impact on different aspects of the business. Predictive analytics aid in optimizing inventory levels through improved sales forecasting. It offers smart alerts for low-stock Stock Keeping Units (SKU) based on the supplier lead time. It enhances warehouse planning and boosts order management and fulfilment efficiency.

In general, supply chain analytics offers advantages with immediate and enduring benefits at all levels of the supply chain. The valuable insights offer businesses various chances to enhance workflows, recognize risks, anticipate current and future issues, and have a notable effect on profits. It helps them become more focused on customers and transition to a data-based decision-making approach to become profitable.

Optimized Transportation and Logistics:

This component plays a crucial role in SCM and has the potential to impact every other aspect. Supply chain analytics help comprehend the reasons for and financial impact of transportation delays to develop effective solutions. Increasing the speed of material movements to align with fluctuations in demand can enhance cash flow for companies. Identifying different suppliers and improving contract negotiations are connected to simplifying procurement processes. Together, these actions will boost the working capital of businesses.

Cost Reduction and Operational Efficiency:

Eliminate silos and gain real-time insight into the siloed data that powers operational performance and provides actionable insights to drive continuous integrated planning.

The intricate nature of supply chains makes it challenging to oversee the entire process and creates opportunities for errors within the system. Moreover, sophisticated shipping analytics uncover chances to save costs and enhance decisions. It transforms data into valuable insights, and this results in cost reduction.

- Every type of data analytics has a vital role to play.

- Descriptive analytics utilizes data to depict occurrences and recognize patterns and trends.

- Forecasting analytics anticipate upcoming occurrences. This enables the prediction of demand and management of inventory.

- Prescriptive analytics recommend what steps to follow based on that data.

Improved Supplier Management:

Supply chain analytics has turned out to be a chief pressure in these days’s enterprise world, influencing the way companies manipulate supply chain control. Modern trends consisting of AI (artificial intelligence), machine studying, and real-time analytics have modified the dynamics of traditional delivery chains.

Risk Mitigation and Resilience:

However, supply chain analytics identifies known risks and predicts destiny risks with the aid of identifying patterns and developments across the delivery chain.

Identifying patterns and trends in the supply chain management helps prevent significant risks and improve risk assessment in your organization’s daily operations. And a lot of these viewpoints – these areas of risk – remain undisclosed to the manufacturer until the data is gathered correctly.

Supply chain analytics can alert a supply chain manager about a significant upcoming problem long before it occurs, leading to cost and time savings for the company.

Data-Driven Decision-Making:

Supply chain analysis can help an organization better forecast future demand by analyzing customer data. It can help an organization understand which products can be reduced in quantity when they are not unprofitable, or it can help an organization understand what customer needs are after an initial order

Data-driven decision-making uses data, metrics and insights to guide strategic business decisions to align with goals, plans and projects

It is a process that involves analyzing data from market research and gaining insights that will benefit the business or organization.

Conclusion

Appvin, a leading provider of solutions for managing supply chains, plays a vital role in assisting organizations in effectively utilizing analytics. Nonetheless, Appvin Technologies offers various advanced analytics tools and technologies tailored for supply chain management requirements, allowing businesses to leverage their data for strategic decision-making and operational success. Appvin’s contemporary delivery chain analytics platform enables groups to reveal their supply chain operations in real time, pinpoint inefficiencies, and decorate overall performance throughout all sectors. In addition, the platform gives records on predicting call for, optimizing inventory, coping with transportation logistics, and dealer control to assist agencies in closing aggressively inside the modern-day evolving market.

FAQs

What role does analytics play in supply chain optimization?

Supply Chain Analysis (SCA) is a set of frameworks and tools for integrating and analyzing data across multiple systems to gain insights into sourcing, processing and distribution When you combine data from your SCM and ERP applications, it provides you get a comprehensive view of your logistics ecosystem.

What are some key analytics techniques used in supply chain optimization?

Some key analytics strategies consist of predictive analytics, prescriptive analytics, descriptive analytics, gadget studying, optimization algorithms, simulation modelling, and information visualization. These techniques help organizations analyze big volumes of facts, perceive styles, and make knowledgeable choices to optimize their delivery chain operations.

What are the benefits of using analytics in supply chain optimization?

The benefits of using supply chain analytics in optimization consist of progressed forecasting accuracy, reduced stock carrying costs, superior operational performance, better overall performance control, optimized transportation routes, multiplied client delight, and typical fee financial savings.

How does analytics help in inventory management?

Analytics enables stock control with the aid of analyzing historical sales information, lead times, supplier overall performance, and calls for variability to optimize stock levels. By implementing techniques inclusive of ABC evaluation, protection inventory optimization, and reorder factor calculation, agencies can decrease sporting prices at the same time as ensuring product availability.

How does analytics help in cost Reduction and Operational Efficiency?

Analytics performs a substantial function in value reduction and operational performance inside the supply chain by offering insights and enabling fact-driven decision-making.