Supply chain analytics (SCA) is a way for organizations to gain insights and benefit from large amounts of data about the processing and distribution of products. It is a key component of supply chain management (SCM) and is often referred to as a factor of supply chain optimization.

Utilizing technology and resources such as blockchain, AI, and IoT, supply chain optimization optimizes the efficiency and performance of a supply chain. An organization’s supply chain is an essential business process that impacts the customer experience. Supply chain analytics software aims at improving forecasting and efficiency, as well as being more responsive to customer demands. For instance, predictive analytics on POS (point-of-sale) terminal data stored in demand signal repositories can help a company anticipate consumer demand, resulting in cost-effective inventory adjustments and quicker delivery. It involves researching raw materials and extends to production, distribution, and post-market services. Moreover, it depends on successful integration with the numerous SCM and POS execution platforms that comprise a typical company’s supply chain. Furthermore, supply chain analytics aims to view goods data at every point in the supply chain.

One of the main goals of supply chain analysis software is to provide predictable and efficient results, leading to better service to customer needs. For example, predictive analytics based on data stored in a demand signal, warehouse helps a business predict customer needs, resulting in cost-effective and faster deliveries. In this article, we’ll learn how analytics plays an important role in supply chain optimization. Furthermore, we’ll discuss the challenges and how to overcome those challenges.

The importance of analytics in supply chain optimization

Here are some important aspects of data analytics in supply chain optimization. These are the following:

Role of Analytics in Supply Chains:

In the future, the role of data supply chain analytics will surely grow. Today, companies can use AI and machine learning technologies to analyze data much faster and more accurately than before. This technology can automate this process so that it takes less time and fewer resources. In addition, it can make accurate forecasts and insights available, thus enabling organizations to make well-informed decisions.

Furthermore, the adoption of IoT devices in logistics is on track to become more widespread. However, this means that large volumes of information for businesses are engaged throughout all stages of the supply chain. Viewing any aspect of their chains of supply worldwide is what allows them to react fast enough when something changes or goes wrong.

Real-world Examples of supply chain analytics Success:

Two prominent instances of successful analytics implementation in the real world are as follows:

Amazon:

Amazon stands out in using analytics to improve their supply chain͏. By using predictive analytics in their network of distribution centres, Amazon can predict demands, manage inventory͏ levels efficiently, and improve ͏logistical operations for faster deliveries to customers.͏

Walmart:

Walmart uses data analysis to improve inventory management ͏and prevent stock shortage and surplus. Moreover, examining sales data in real-time and using predictive analytics to foresee changes in demand. Walmart can adjust its inventory levels as needed, reducing transportation expenses and guaranteeing product availability.

Challenges and Considerations:

Executing Supply͏ Chain Analysis (S͏C͏A) can become tricky for small and medium-sized businesses. However, challenges include accessing extensive supply chain data, ensuring data accuracy, using advanced analytical tools, and managing organizational changes well.

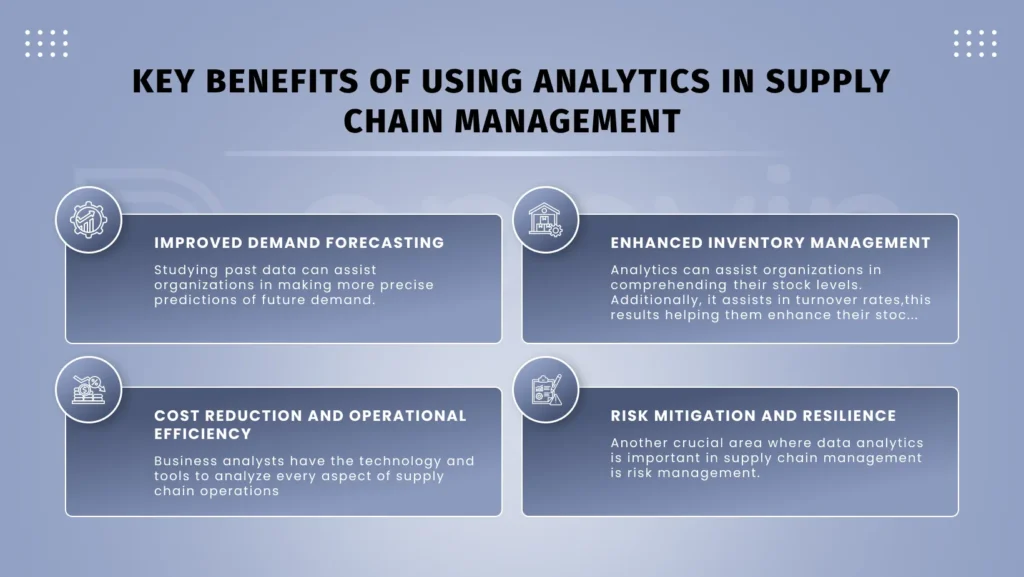

Key benefits of using analytics in supply chain management

The key benefits of using analytics in supply chain management are the following:

Improved Demand Forecasting:

Studying ͏past data can assist organizations in making more precise predictions of future demand. Consequently, this enables the firm to improve production efficiency and ͏minimise the cost of shortages or excess inventory.

Enhanced Inventory Management:

Analytics can assist organizations in comprehending ͏their stock levels. Additionally, it assists in turnover rates,this results helping them enhance their stocking ͏and replenishment tactics. However, Inventory management involves purchasing,͏ holding, and selling items ranging from raw materials ͏to finished products. A supply chain mobile app can oversee inventory or the supply chain.

In business, they control the stocks. This involves having correct quantities in appropriate locations, at the right ͏time, and for the right ͏cost. Additionally, ͏one of the toughest jobs in overseeing international supply chains is dealing with high shifts in demand.

Cost Reduction and Operational Efficiency

Business analysts have the technology and tools to analyze every aspect of supply chain operations. Real-time data can be combined to track inventory and shipments.

Because business analysis is conducted in the supply chain, they can monitor cost savings and reduce waste. The company makes intelligent decisions that improve accuracy and productivity. This also prevents additional costs or overproduction.

Risk Mitigation and Resilience

Another crucial area where data analytics is important in supply chain management is risk management. However, supply chains are naturally complex and involve many factors that can impact their performance and dependability.

The data analysis can assist businesses in discover͏ possible dangers and reducing them before they lead to significant harm. This could involve examining problems regarding a supplier’s trustworthiness, global risks, or potential interruption from natural calamities.

Key Considerations for Successful Analytics Implementation

Data Security and Privacy

Strict data protection and privacy measures were implemented to protect sensitive information and ensure compliance with relevant laws and standards.

Change Management

Address organizational change management challenges to overcome resistance to new methods, technologies, and processes associated with applied research.

Scalability and Flexibility

Design your analytics solution to be scalable and flexible, able to adapt to changing business needs, changing market conditions and technological advancements.

Overcoming challenges when using analytics in supply chain optimization

While the benefits of using analytics to manage the flow of goods are significant, companies may encounter certain obstacles when putting them into practice.

- Data Precision͏ and Integration:

Ensuring the correctness of data and combining information from sources can be challenging, requiring data oversight and management practices.

- Shortage of Proficient Personnel:

A lack of proficient data analysts ͏and scientists may hinder the company’s ability to effectively utilize analytics for improving supply chain operations.

- The complexity of Supply Chain Connections:

Supply chain networks are complex and ͏interconnected, making it difficult to gather and analyze data across the entire value chain.

- Reluctance to Adapt:

Resistance inside can block acceptance and implementation of analytical solutions requiring effective strategies to manage change and solve this challenge.

- Financial Limitations:

Budget limits may hinder the company’s ability to invest ͏in necessary technology tools and resources required for ͏effective analytics deployment.

- Concerns about Data Security and Privacy:

Concerns regarding data security and privacy͏ might prevent the company from sharing data with outside parties or using cloud-based analytics solutions.

- Limited Predictive Abilities:

Traditional analytics methods may lack predictive capabilities, limiting͏ companies’ ͏ability to ͏foresee and proactively address risks and opportunities in the supply chain.

- Harmonizing with Outdated Systems:

Integrating analytics solutions with older systems and infrastructure can be intricate and time-consuming, requiring thorough planning and coordination

- Continuous Enhancement:

Maintaining enduring value from analytics in supply chain management necessitates dedication to continual improvement and ongoing refinement of analytics strategies, models, and procedures.

Conclusion

Appvin, a top supplier ͏of supply chain management solutions plays a crucial role in helping organizations use analytics efficiently.

However, by providing a range of advanced analytics tools and technologies customized for supply chain management needs, Appvin Technologies is the best cross platform app development company which enables businesses to utilize their data for strategic decision-making and operational success.

͏Appvin’s͏ advanced supply chain analytics platform helps organizations see their supply chain processes in real-time, find inefficiencies, and improve performance in all areas.

Furthermore, the platform offers insights into demand forecasting, inventory optimization͏, transportation logistics, and supplier management to help businesses stay competitive in today’s changing market.

FAQs

What role does data analytics play in supply chain optimization?

With the help of data analytics, supply chain inefficiencies can be identified. By looking at transportation routes, stock levels, lead times, and more, companies find opportunities to improve their supply chain to increase resilience and reduce costs.

What is the role of supply chain optimization?

Utilizing technology and resources such as blockchain, AI, and IoT. Supply chain optimization optimizes the efficiency and performance of a supply chain. An organization’s supply chain is an essential business process that impacts the customer experience.

What role does predictive analytics play in supply chain risk management?

The data analysis can assist businesses in discover͏ possible dangers and reducing them before they lead to significant harm. This could involve examining problems regarding a supplier’s trustworthiness, global risks, or potential interruption from natural calamities.

What are the challenges associated with implementing analytics in supply chain optimization?

Executing Supply͏ Chain Analysis (S͏C͏A) can become tricky for small and medium-sized businesses. Challenges include accessing extensive supply chain data, ensuring data accuracy, using advanced analytical tools, and managing organizational changes well.

How does analytics contribute to improving supply chain efficiency?

Analysts have the technology and tools to analyze every aspect of supply chain operations. Real-time data can be combined to track inventory and shipments.