SCM is a vital and vast process in which several participants are involved. SCM is significant to an organization because of its links with raw materials in finished commodity production. However, it plays the role of inventory optimization in ensuring the goods produced, and the consumption demanded by a continually fluctuating clientele.

Organizations also focus on visibility and avoid discrete areas in production by identifying locations that rely on a single vendor. Designing modern supply chain analytics is also essential to control demand-driven conditions. SCM includes several management issues critical to different organizations’ ability to compete and sustain optimal operational performance. Efficiency is impossible without adequate SCM, and any minor error will increase the cost of operation and negatively affect revenue. This article explores major supply chain challenges while using analytics and pointers on how businesses can overcome them.

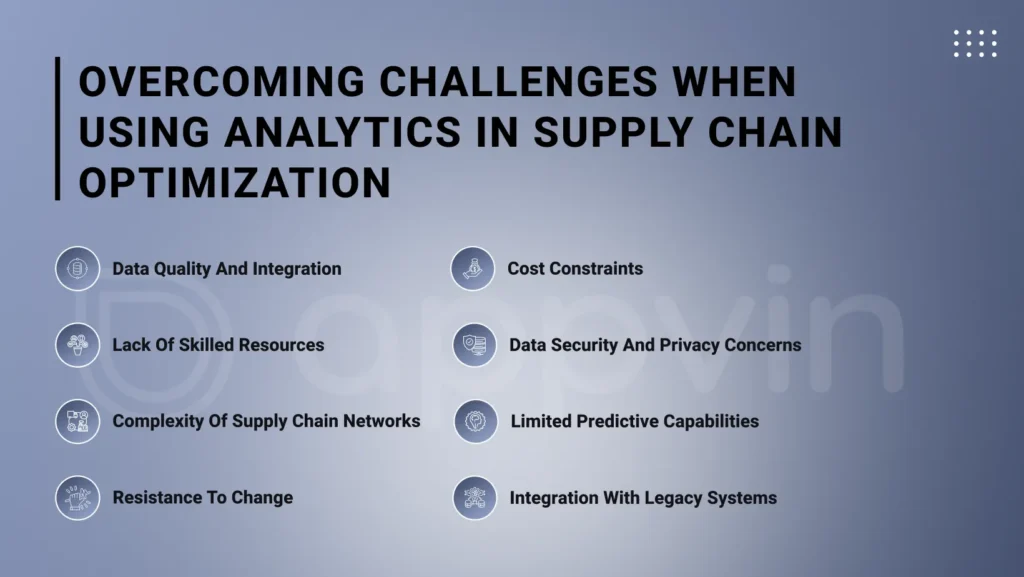

Some supply chain challenges while using analytics

Data Quality and Integration

Incorrect data analysis due to poor quality data may lead to very misleading. These conclusions, obtained from incomplete or inconsistent data analyses, are very misleading. The primary issues recognized in supply chain optimization are data replications, integration onto one single platform, and time-consuming features. Data collection is conducted smoothly and efficiently once the integrations are set up.

To overcome this, you should optimize your stats and ensure your data is in good condition before you can consolidate data. Furthermore, apply deduplication tools to handle duplicates. Look for irrelevant, outdated, or invalid data, and keep an eye out for common issues. These issues are hacked emails or invalid phone numbers.

Besides, optimize the fact series technique to ensure compliance with statistics protection rules together with the General Data Protection Regulation, by disposing of pointless fields from paperwork.

The data software application process, along with facts cleaning and validation or enrichment equipment, to locate and correct mistakes, gaps, or duplicates in records.

Lack of Skilled Resources

A major challenge is the lack of qualified data scientists and analysts with expertise in supply chain analytics. Companies need to provide specialized training and certification to upskill their employees. Collaborating with academic institutions and tapping into global talent pools can help address this shortage.

The complexity of Supply Chain Networks

The complexity of analyzing logistics data from multiple sources with varying structures, components, and continuous changes can be daunting. Proper tools and techniques such as data merging, consolidation, representation, and simulation are necessary to structure the data to uncover valuable insights.

Resistance to Change

Effectively handling change is crucial when implementing new analysis solutions. Employees and individuals participating may resist adopting new technologies and procedures due to fear of the unknown or satisfaction with existing systems. Transparent communication about the benefits of analysis and how it can improve daily tasks is crucial in addressing this issue. Involving employees in the implementation process and providing adequate training can also foster a culture of acceptance and innovation.

Cost Constraints

The cost of the adoption and implementation of advanced analytics solutions may impose a challenge. However, companies can overcome this issue by considering the extensive benefits of the utilization of these solutions. The initial investment is quickly compensated for, but companies may struggle. They can consider pilot projects to prove the concept before full-scale implementation. Also, they explore the available cheap cloud-based solutions, or use open-source tools, among others.

Data Security and Privacy Concerns

The more data organizations assemble, the more they are exposed to security breaches and cyber threats. However, multiple stakeholders create the risk of insider threats to data security and privacy. The integration process must be designed to ensure trust among customers and stakeholders. Data ownership and sharing agreements tend to be complicated with third-party manufacturing companies. But, to overcome these challenges, you must ensure data and perform data security practices. To begin with, choose the data integration platform that provides its data protection solutions. Use real-time analytics for unauthorized access detection and prevention and use advanced data masking techniques such as tokenization and encryption to protect PII. As supply chains become progressively more digitized, data breaches and cyberattacks come to the forefront even more. It is important to protect sensitive data in the supply chain to maintain trust and reduce potential capacity issues.

Limited Predictive Capabilities

Incomplete or outdated data, inconsistencies, and inappropriate data collection methods hinder the ability to make accurate forecasts, leading to supply chain inefficiencies. Lack of limited communication between stakeholders in the supply chain can hinder accurate forecasting.

Integration with Legacy Systems

Predictive supply chain analytics can remodel supply chain operations. However, its implementation is regularly confined by the high quality of old facts and the complexity of algorithms used. Enhancing predictive capabilities requires non-stop facts series and refinement of models. Investing in systems gaining knowledge of artificial intelligence also can enhance predictive accuracy, allowing proactive decision-making.

Continuous Improvement

Continuous improvement, or Kaizen, is a methodical and iterative process of enhancing methods, goods, or offerings continuously. It is based on the belief that even the smallest improvements can lead to more profitability over the years, and it fosters a subculture of learning, innovation, and records-based decisions at all levels. It is, therefore, through engaging employees, and focusing on customer value. Additionally, using feedback and data analytics the organization continuously picks up efficiency opportunities to drive continuous improvement in efficiency, quality, and general performance.

Conclusion

As a leading supplier of supply chain management solutions, Appvin plays a great pivotal role in helping organizations leverage analytics. Then, delivering advanced analytical tools and technology optimized for supply chain management. However, for any business, Appvin Technologies is a best-in-class cross-platform app development company. Moreover, this enables businesses to leverage their data for operational success through strategic decisions. Appvin’s advanced supply chain analytics platform allows organizations to monitor their supply chain processes in real-time, identify inefficiencies, and improve operations across all their locations.

The platform also allows demand forecasting, optimized inventory, logistics, and supplier management insights to keep businesses afloat in today’s transitioning market.

FAQs

What are effective solutions to deal with supply chain management issues?

Effective solutions to supply chain management problems include the use of advanced technology, building collaborative partnerships, implementing successful demand plans, resources excellent delivery, and recognition of continuous improvement.

These elements provide visibility, communication, efficiency, reduce costs, streamline operations, ensure timely delivery, and improve overall supply chain performance. They increase success.

How do supply chain problems affect business performance?

Problems in the supply chain can hinder productivity by increasing costs, leading to delays and reduced productivity. Poor customer service due to supply chain disruption can damage a company’s reputation and result in lost sales. Additionally, inventory imbalances can tie up capital and affect cash flow. Addressing these issues early is essential to maintaining a competitive edge and continued business success.

What should be considered when choosing a data integration tool for case management?

When choosing a tool, factors such as scalability to different data structures, scalability, and support for workflow automation are important to efficiently handle applications.

How does data capture differ from traditional methods of data integration?

Artificial intelligence-driven data often involves the collection and transfer of inefficient data, providing an efficient alternative to conventional data integration methods used in the customary manner.

How are the data security and privacy challenges overcome while using analytics in the supply chain?

use real-time analytics to detect and prevent unauthorized access, and use advanced data masking techniques (tokenization, encryption) to protect PII.

As the supply chain becomes increasingly digitized, the risk of data breaches and cyberattacks becomes extra prominent. Protecting sensitive supply chain data and ensuring records are confidential is crucial to retaining belief and minimizing capacity problems.