Logistics & supply chain, foundation international business, suffers difficulties hampering smooth operation, increasing cost processes. Such; as accuracy in real-time processing of information goods location or condition (tracking), prediction errors future demand volumes commodities among others last-mile delivery systems Artificial intelligence has become a game changer, dealing with challenges by providing creative ways to improve efficiency within the transportation industry. Logistics is complex by nature since brings together different people at different times and different needs (stakeholders), making them want things done faster.

This article explores how AI and machine learning technology enhance supply chain efficiency, as well as key considerations leveraging this powerful technology in supply chain businesses.

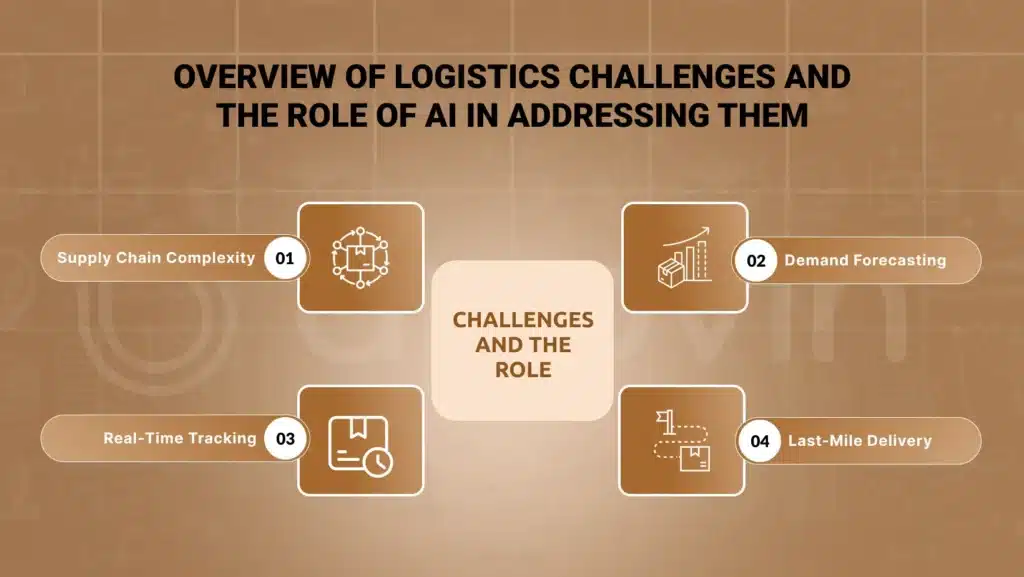

Overview of logistics challenges and the role of AI in addressing them

Logistics operations are naturally complex and involve many stakeholders, different demand patterns, as well as the need for punctual delivery. Here are some of the top challenges:

Supply Chain Complexity:

Managing a globalized supply chain involves dealing with numerous suppliers, manufacturers, and distributors who are often located in different time zones and under various regulatory regimes.

Demand Forecasting:

Incorrect predictions about demand may result in either overstocking or stockouts thereby affecting service levels and profitability.

Real-time Tracking:

It is important to maintain visibility across the entire logistics network but this is usually not achievable using traditional methods which leads to inefficiencies and delays.

Last-mile Delivery:

Final stage delivery tends to take up most time and money with significant challenges such as route optimization and timely deliveries.

These problems can be solved by AI and machine learning in the supply chain through analyzing big data sets, insights generation, process automation, and logistical activities optimization.

AI applications in logistics and transportation:

The main objectives of applying AI to supply chain and logistics are productivity increases and efficiency. However, given increased sustainability integrating AI into supply chain management, all firms now doubt the potential benefits of digital transformation for operations.

Complex algorithms utilized to incorporate AI and machine learning in the supply chain ecosystem. AI and machine learning in the supply chain-based solutions will improve data quality, and present a new perspective on warehouse and supply chain. Additionally, it can provide quick replenishment of the ideal inventory levels and requirement forecasting.

Real-time tracking and visibility

The use of AI and machine learning in the supply chain improves the situation here by orders of magnitude, significantly increasing real-time tracking and visibility. IoT facilitates constant tracking of shipments using AI systems. Transport and even containers themselves began to be equipped with various sensors. Thus, the companies have live information about the movement of goods, which allows for extremely accurate updates. AI algorithms analyze GPS data, and RFID tag information to find the likelihood of emergence delay points, and dynamically rebuild optimal routes. The same transparency allows for making stable shipment estimates for customers, successfully solving unprecedented problem levels due to quick digitalization.

Data integration and analysis:

AI systems obtain information sources such as Global Positioning System (GPS), Radio Frequency Identification (RFID) tags, Internet of Things (IoT) sensors, and traffic control systems. When this data is processed in real-time by AI and machine learning in the supply chain, manufacturer-to-end user pictures the entire supply chain event achieved.

Prediction Analysis:

To improve delay and problem awareness, analytics creates a predictive watch. Considering such procedural aspects as analysis of the prior data and the account of the present scenarios. Nevertheless, special AI algorithms can ascertain traffic conditions, weather, as well as other factors that may influence delivery times. This allows the logistics managers to prevent or reduce probable causes of delay and develop new strategies for handling each of the heritages.

Dynamic approach to efficiency:

AI and machine learning in the supply chain can plan the route while on route and it is capable of rearranging plans depending on which time, road, area or city there is a traffic jam or when there is any closure of road amongst others. This leads to certain delivery convenience to the various destinations hence fuel efficiency and time consumed in delivery.

Improved customer experience:

Using real-time tracking customers get track information as soon as it is available. Such transparency ensures the reduction of uncertainty through the establishment of precise time delivery, increases confidence, enhancing customer satisfaction.

Supply Chain Resilience:

Shipment visibility employing artificial intelligence enables prompt intervention in crises like natural disasters or supply chain disruptions. When disruptions occur, logistics continue uninterrupted since necessary shipping alterations can be initiated immediately.

Autonomous vehicles and drones for last-mile delivery

Self-driving delivery motorcars or robotic driver-less motorcars with artificial intelligence technology can effectively navigate through city, traffic, hence cutting costs, and time delivery. They allow for steer and access to far-off or crowded places thus getting around the conventional traffic challenges. However, these machines incorporate modern artificial intelligence abilities for pathfinding, avoiding obstacles, and planning routes to deliver passengers safely, and on time. It enhances delivery process effectiveness, helps fuel consumption usage with precise optimization towards emissions reduction, curbing environmental air pollution from transport.

Conclusion

Appvin solution is a commonly trusted supplier chain solution where that serves a significant role in helping firms leverage analytics.

However, Appvin Technologies can offering a wide range of exclusive AI and machine learning in the supply chain solutions, particularly supply chain management needs unique options. This makes it possible for organizations coordinate-based data, and come up with strategic directions for successful operations. Appvin’s supply chain analytics platform helps organizations glimpse supply chains in real-time, and analyze findings on efficiency issues or melioration aspects of the business. Addition offers data prospecting, stocking, furnishing appropriate transport means, and supervising suppliers to help companies stay relevant present economy.

FAQs

What contribution does AI make in improving real-time monitoring and transparency in the logistics industry?

AI and machine learning in the supply chain combines GPS information, RFID tags, IoT sensors, and other inputs to give a detailed, real-time picture of the supply chain. It employs prescriptive analytics to predict possible flight delays and adjust the most effective paths in real-time.

How does AI improve demand forecasting in logistics?

AI incorporates past data, market data, and other relevant external data to forecast the demands more effectively. This results in proper stock management thus preventing overstocking and situations where there is no stock.

What are the benefits of real-time tracking for customers?

Real-time tracking services allow customers to track delivery times accurately, making delivery timely, consistent, and accurate, increasing customer satisfaction.

Where and how does the use of autonomous vehicles enhance last-mile delivery?

Self-driving cars with artificial intelligence help measure routes and avoid any hindrances on the road, decreasing delivery time and expenses. They also help in reducing emissions especially if the vehicles are electric.

What is the mechanism of dynamic route optimization systems that apply artificial intelligence?

These systems use real-time information on traffic conditions, weather, and road networks to constantly recalibrate delivery routes efficient, fuel-friendly, timely manner.